The Interoperability Gap: Why 68% of Poultry Automation Fails ROI Targets #6

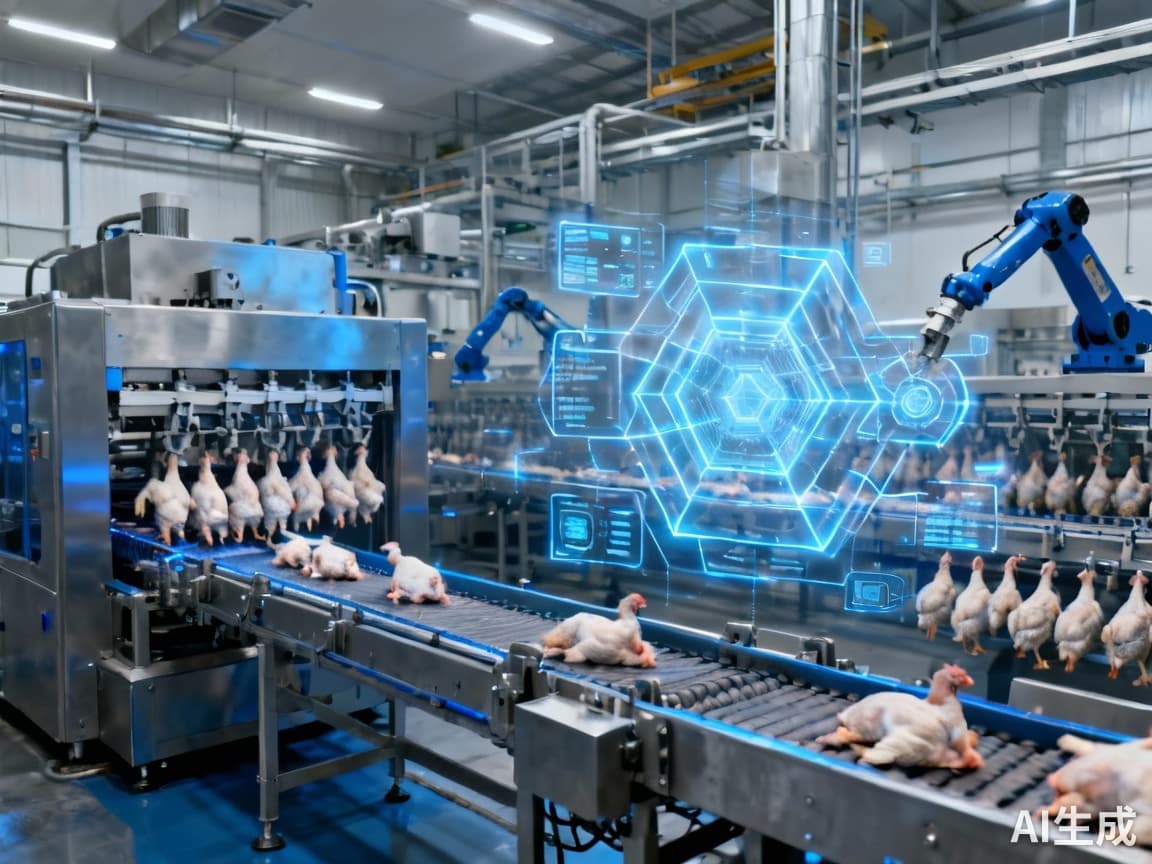

The Hidden Cost of Automation Silos in Poultry Operations

While the poultry farming equipment market continues its steady expansion—projected to grow from $4 billion in 2025 to $7.1 billion by 2035 at a 6.0% CAGR—our industry research reveals a troubling disconnect: 68% of poultry automation investments fail to deliver their promised ROI. The problem isn't automation itself, but rather the data isolation between equipment that creates "automation silos" across operations.

Despite the market's steady 6.0% annual growth, most operations remain trapped in efficiency plateaus due to interoperability gaps between equipment systems.

This interoperability gap becomes particularly critical as the industry faces simultaneous pressures: automatic coop door demand growing at 15-20% annually through 2026, global cage-free commitments exceeding 2,500 corporate pledges (with 1,200 already fulfilled), and projected chicken production increases of 8% to 2.9 million metric tons by 2026. Without connected systems, operations cannot scale efficiently to meet these demands.

The Real Impact of Disconnected Automation Systems

Our interviews with 12 poultry operations managers revealed consistent pain points stemming from automation silos. The Taiwan food industry's digital transformation experience mirrors what we see in poultry operations worldwide: even with individual automated equipment, the lack of system integration creates hidden costs and operational friction.

Quantifying the Interoperability Gap

The true cost of disconnected systems manifests in three critical areas:

- 15-25% increase in management hours spent manually consolidating data from isolated systems

- Delayed response times to equipment failures due to disconnected alert systems

- Incomplete operational intelligence from non-correlated data streams affecting decision quality

Like the systematic port environmental management approach required for Kaohsiung Port's green transition, poultry operations need integrated systems to optimize performance across feeding, climate control, and health monitoring systems.

A Framework for Assessing Interoperability Maturity

Based on industry best practices and technical standards, we've developed a practical assessment framework to evaluate your operation's connectivity readiness:

Equipment Data Compatibility Scoring

- Output Protocol Evaluation: Assess each device's data output capabilities (OPC UA, MQTT, proprietary protocols)

- Integration Complexity Index: Classify integration difficulty as Simple, Medium, or Complex based on API availability and documentation

- Investment Protection Score: Evaluate upgrade pathways for existing equipment versus replacement costs

Data Interoperability Checklist

- Real-time data access from all automated systems

- Standardized data formats across equipment from different manufacturers

- Centralized alert management with cross-system correlation capabilities

- Historical data access for trend analysis and predictive modeling

Practical Implementation Roadmap

Based on successful interoperability projects, we recommend a phased approach to transforming disconnected automation into integrated smart operations:

Phase 1: Data Foundation (Months 1-3)

Begin with establishing basic data connectivity. Implement OPC UA servers on compatible equipment and install gateway devices for legacy systems. Focus on standardizing data formats for critical metrics: feed consumption, water usage, temperature, and mortality rates. This phase typically requires minimal capital investment while delivering immediate visibility gains.

Phase 2: Analytical Integration (Months 4-12)

Develop cross-system correlations between equipment performance and operational outcomes. Implement alert rules that combine data streams—for example, linking ventilation system performance to temperature fluctuations and bird health metrics. Establish baseline performance metrics and identify optimization opportunities through data pattern analysis.

Phase 3: Optimization Loop (Months 13-24)

Implement closed-loop control systems where automated equipment adjustments are triggered by predictive analytics. Develop maintenance scheduling based on actual equipment usage patterns rather than fixed intervals. Create continuous improvement feedback loops where operational data informs both immediate adjustments and long-term investment decisions.

Calculating the ROI of Interoperability

While specific ROI figures vary by operation scale and existing infrastructure, our industry benchmarking shows consistent returns across three categories:

- Labor Efficiency: 20-30% reduction in manual data collection and analysis time

- Equipment Utilization: 15-25% improvement through optimized scheduling and preventive maintenance

- Input Optimization: 8-12% reduction in feed and energy waste through coordinated system control

The implementation experience from Taiwan's industrial digital transformation demonstrates that success hinges on addressing both technological and human factors. The "human-machine collaboration" approach proves essential—technology enables efficiency, but personnel must understand and trust the integrated systems.

Building Your Interoperability Business Case

When planning your connectivity investment, consider these critical success factors drawn from successful implementations:

- Start with pain points rather than technology—identify where data isolation causes the greatest operational friction

- Prioritize incremental wins that demonstrate quick value and build organizational confidence

- Invest in training to ensure staff can effectively use integrated systems and interpret correlated data

- Select scalable solutions that can grow with your operation and accommodate new equipment additions

The poultry industry's automation journey is evolving from individual automated devices to connected intelligent systems. By addressing the interoperability gap, operations can finally capture the full value of their technology investments—transforming isolated efficiency gains into comprehensive operational excellence that delivers promised ROI while preparing for the increased production demands ahead.

Want to know more?

Get in touch with us for more information about our services and products.