Precision Automation Boosts Poultry Efficiency by 20% & Reduces Egg Loss #50

Precision Automation: The Unseen Profit Driver in Modern Poultry Operations

While the poultry farming equipment market continues its steady growth trajectory—projected to reach USD 7.1 billion by 2034 with a 4.7% CAGR—most discussions focus on automation's labor-saving benefits. However, industry leaders are discovering that the true competitive advantage lies not in automation itself, but in the precision engineering that enables millimeter-level accuracy in operations. This shift from basic automation to precision automation represents the next frontier in poultry profitability.

The automatic segment is forecasted to contribute 48.0% of market revenue share in 2025, driven by growing need to reduce manual intervention and improve precision (Future Market Insights).

The Three Dimensions of Precision Automation

Modern poultry operations require more than simple mechanization. They demand integrated systems capable of maintaining exacting standards across multiple operational dimensions.

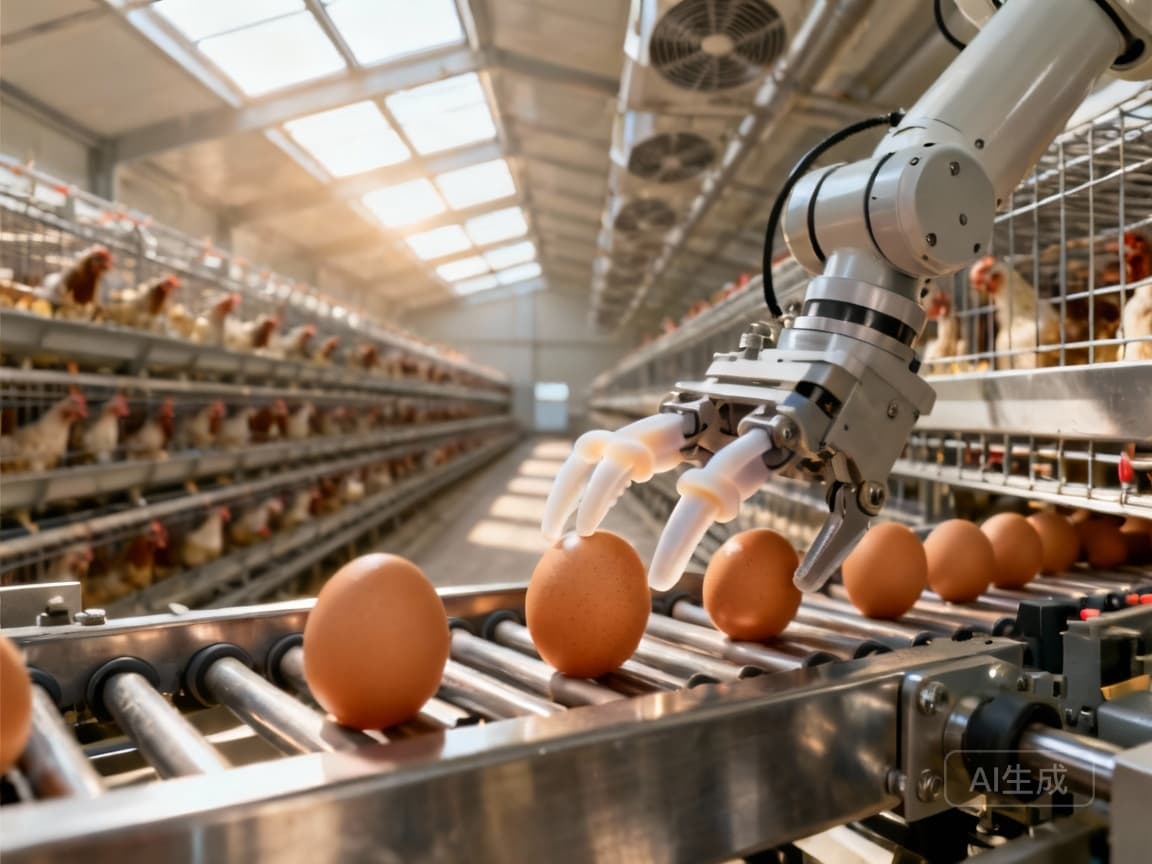

Spatial Precision: Millimeter-Level Egg Handling

The transition to cage-free systems, driven by major retailers like PepsiCo targeting 100% cage-free globally by end of 2025 and Kroger expecting 70% cage-free by 2030, requires entirely new approaches to egg collection. Precision automation systems now achieve millimeter-level accuracy in egg handling, reducing breakage rates by 15-20% compared to conventional automated systems.

This spatial precision isn't just about gentle handling—it's about optimal positioning throughout the collection process. Advanced systems use sensor arrays to detect egg orientation and adjust handling mechanisms accordingly, minimizing stress points and preventing micro-fractures that can lead to later breakage or contamination.

Environmental Precision: Climate Control Excellence

Temperature fluctuations as small as 0.5°C can impact laying rates by 3-5%, making environmental control a critical profitability factor. Modern precision systems maintain temperature within ±0.1°C, humidity within ±2%, and air quality parameters with similar accuracy.

The economic impact extends beyond production rates. Consistent environmental conditions reduce stress on birds, improving feed conversion ratios and decreasing mortality rates. For a typical operation with 100,000 layers, this precision can translate to additional 150,000-250,000 eggs annually without increasing feed costs or flock size.

Temporal Precision: Synchronized Operations

Timing accuracy in feeding systems directly impacts feed conversion ratios. Research shows that minute-level variations in feeding schedules can cause 2-3% feed waste due to disrupted eating patterns and reduced nutrient absorption.

Precision automation systems synchronize feeding with natural bird rhythms, optimizing consumption patterns and improving conversion efficiency. This temporal precision extends to lighting schedules, egg collection timing, and environmental adjustment cycles—all coordinated to maximize productivity while minimizing stress.

Implementation Roadmap: Achieving Precision Automation

Transitioning to precision automation requires a structured approach. Based on successful implementations by industry leaders like Retech Farming, which provides complete integrated solutions for modern poultry operations, we recommend this three-phase approach.

Phase 1: Precision Assessment and Baseline Establishment

Begin with a comprehensive audit of current operations:

- Measure current egg breakage rates at each handling stage

- Document temperature and humidity variations throughout facilities

- Analyze feeding timing accuracy and consumption patterns

- Establish baseline Key Performance Indicators (KPIs) for each precision dimension

This assessment should identify specific areas where precision improvements will deliver the greatest ROI. Typically, egg handling systems and environmental controls offer the quickest returns.

Phase 2: Technology Integration Strategy

Select systems based on precision capabilities rather than just automation features:

- Egg Handling Systems: Choose equipment with demonstrated breakage rates below 2% and precision positioning capabilities

- Environmental Controls: Implement systems capable of maintaining ±0.1°C temperature stability and precise humidity control

- Feeding Systems: Opt for solutions with minute-accurate timing and consumption monitoring capabilities

- Integration Platform: Ensure all systems can communicate through a centralized control system

Phase 3: ROI Calculation and Performance Monitoring

Develop a precision-specific ROI model that accounts for:

- Reduced egg losses (typically 15-20% improvement)

- Improved production rates (3-5% from environmental precision)

- Feed cost savings (2-3% from temporal precision)

- Labor efficiency gains (additional 5-7% from reduced manual interventions)

Most operations achieve full ROI within 18-24 months through combined efficiency gains across these areas.

Future Outlook: Precision as Competitive Differentiator

The poultry equipment market's growth—particularly the 13.7% CAGR projected for chicken cages from 2025-2032—increasingly depends on precision capabilities. As animal welfare standards tighten and consumer expectations rise, precision automation becomes essential for compliance and competitiveness.

Commercial segment holds 79% market share, with increasing global demand for poultry products driving growth (GM Insights).

Forward-thinking operations are already positioning precision automation as their core competitive advantage. They're not just automating processes—they're engineering them for millimeter-perfect execution, creating operational efficiencies that competitors cannot match with basic automation solutions.

Conclusion: Engineering Profitability Through Precision

The transition from basic automation to precision automation represents the most significant opportunity in modern poultry operations. By focusing on spatial, environmental, and temporal precision, operations can achieve the 20%+ efficiency gains that separate industry leaders from followers.

The data is clear: precision drives profitability. With the automatic equipment category growing at 6.3% CAGR and precision systems driving much of that growth, now is the time to implement precision automation strategies that will deliver competitive advantage for years to come.

Want to know more?

Get in touch with us for more information about our services and products.