Automate Poultry: Cut Labor 62%, Save 66.7% Water & Unlock IPO Funding #38

Beyond Egg Yield: How Water Recycling and IPO Funding Are Reshaping Poultry Automation

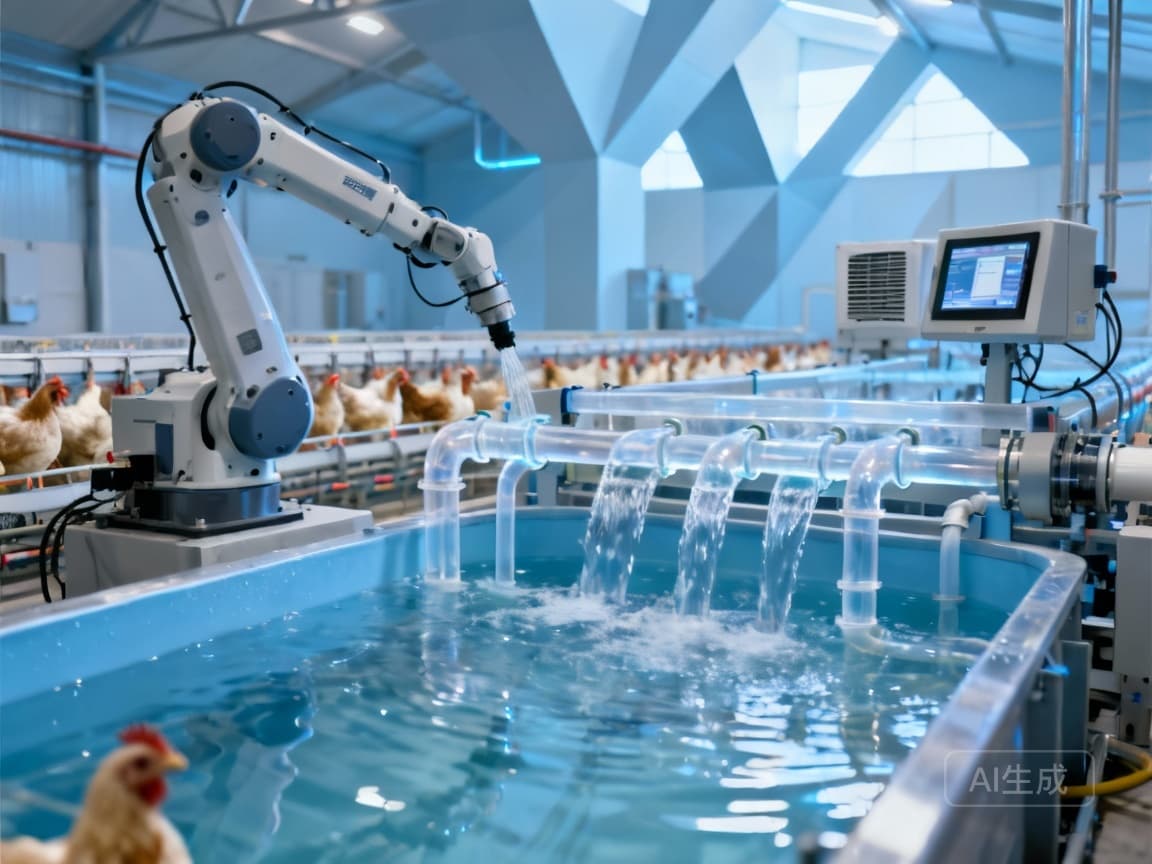

The poultry automation conversation has traditionally focused on labor reduction and egg yield optimization. However, forward-thinking operations are discovering that true competitive advantage lies in mastering three critical resources: water, carbon, and capital. While automatic equipment already commands 48.0% of market revenue share in 2025 according to Future Market Insights, the most successful operations are those that integrate environmental technology with strategic financing.

The Water Management Revolution: From Cost Center to ROI Driver

Water consumption represents one of the most overlooked operational expenses in poultry farming. Traditional systems can use thousands of gallons daily, but innovative approaches are demonstrating remarkable savings. Taiwan's agricultural agencies have implemented two-stage wastewater treatment systems that achieve 66.7% reduction in water usage while simultaneously reducing carbon emissions by approximately 0.4 million tons CO2e.

The market is responding to this need, with search volume for "automatic chicken waterer" rising from 0 to 41 by May 2025, indicating growing awareness of water efficiency solutions. This trend aligns with the broader automatic equipment market growth, projected to reach USD 6,300 million by 2035 with a 6.0% CAGR.

Implementation Framework: Water Recycling Integration

- Assessment Phase: Conduct water usage audit to establish baseline consumption metrics

- Technology Selection: Implement closed-loop water systems with filtration and treatment capabilities

- Monitoring Systems: Install smart meters to track real-time water usage and identify leaks

- Staff Training: Educate operators on water conservation practices and system maintenance

Carbon Reduction as Competitive Advantage

Environmental compliance is transitioning from regulatory requirement to market differentiator. Automated systems naturally support sustainability goals through increased density capabilities—automated cages enable 40% higher bird density per square meter compared to free-range setups, reducing land use and associated carbon footprint.

The European Union and North American markets are particularly sensitive to environmental credentials, with carbon accounting becoming integral to supply chain partnerships. The Taiwan case study demonstrates how wastewater treatment alone can generate substantial carbon reductions, creating potential value through carbon credit markets or green subsidies.

Automated poultry systems reduce daily management time by 62%, from 14 to 5.5 hours weekly per 10,000 birds, while simultaneously addressing environmental metrics that increasingly influence market access and premium pricing.

Capital Strategies: Learning from Qingdao Daman's IPO Success

Equipment modernization requires significant investment, but innovative financing approaches can mitigate capital constraints. Qingdao Daman Machinery demonstrated the viability of public markets for agricultural equipment manufacturers, issuing 50 million shares representing 25% of total post-issuance shares.

This offering occurred within a growing market valued at USD 4.5 billion in 2024 and projected to reach USD 7.1 billion by 2034, representing a 4.7% CAGR. The automatic segment's dominance at 48% revenue share indicates investor confidence in automation technologies.

Financing Implementation Roadmap

- Financial Documentation: Prepare three years of audited financials and operational metrics

- ROI Modeling: Document expected savings from automation (62% labor reduction, 66.7% water savings)

- Regulatory Compliance: Ensure environmental compliance documentation for ESG financing opportunities

- Investor Targeting: Identify green funds and impact investors aligned with agricultural technology

Integrated Investment Framework: Water, Carbon and Capital Synergy

The most successful automation implementations combine environmental and financial strategies. Consider this integrated approach:

- Phase 1: Technology Selection: Choose equipment with integrated water recycling capabilities, using the Taiwan model as reference

- Phase 2: Carbon Accounting: Implement monitoring systems to quantify carbon reduction for ESG reporting and potential credit generation

- Phase 3: Financing Strategy: Structure financing to leverage environmental benefits, potentially through green bonds or sustainability-linked loans

This approach transforms environmental investments from cost centers to revenue-generating assets while addressing the 48% market share that automatic equipment is forecasted to capture in 2025.

Future Outlook: The Resource-Optimized Poultry Operation

The poultry equipment market's progression to USD 7.1 billion by 2034 will be dominated by operations that master resource integration. Seasonal demand patterns already show increased interest in automation solutions, with "automatic chicken feeder" search volume peaking at 100 in August 2025.

Success will require moving beyond isolated efficiency improvements to holistic resource management. The operations that thrive will be those that recognize water conservation, carbon reduction, and strategic financing as interconnected components of modern poultry management, rather than separate operational concerns.

The data clearly indicates the direction: automation is inevitable, but resource optimization is the true differentiator. With labor savings of 62%, water reduction of 66.7%, and proven public market financing options, the blueprint for modern poultry operation success is now clearly defined and data-supported.

Want to know more?

Get in touch with us for more information about our services and products.